|

What we undertake:

Occasionally we purchase antique metronomes with the intention

of undertaking a rework of sorts depending on the current state

of the unit in question. The process can involve anything from a

full over-haul, including the replacement of missing or broken

parts, to full mechanism replacements or in the majority of

cases just a rework of the exterior woodwork. We encounter a

large number of original metronomes that are fully functioning

but have suffered through neglect or poor storage externally,

metronomes that are not up to our high standard's to be able to

list on the website.

This page is intended to hopefully give an insight into the procedure and

some of the issues that we regularly encounter and to show the

results from start to finish. Of course every metronome we

rework is assessed and a course of action determined depending

on the particular metronomes faults but hopefully this one

example should be a good representative example of restoring a

unit that otherwise would be destined for parts or scrapped. Our

REWORKED metronomes are clearly listed on the metronomes

description page.

Hold your mouse pointer over a gallery image for an

enhanced zoom, or click 'play' to listen to your selected

metronome.

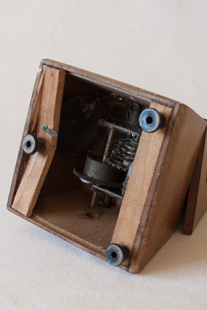

Paquet Cherry Wood Metronome - Attic / Loft Find in Poor Condition. - Circa 1919

This one came to us in non-working order and

was externally water damaged from poor storage in a damp loft, this

metronome left us with no choice but to fully strip the entire

metronome. The original parts and fittings are all in place,

with the lower slat and rear foot damaged, the bell and

mechanism escapement are both completely seized or not working,

partly with thanks to the wildlife living within the mechanism

compartment. Fortunately there is no wood-worm damage or major

splits or chips to the woodwork. ( Pictures 1-4 )

We start by removing all external fittings and the door emblem, hinge etc and

removing the mechanism from the housing compartment. All loose

debris and years of dust and grime are lightly removed with a

fine soft bristle brush from all parts of the external casing

and the mechanism. ( Picture 4 ). The external case / woodwork

is sanded from a medium grit right down to 0000 steel wool. (

Picture 5 ). The mechanism is completely disassembled, we will

not go into our procedure for cleaning the critical

parts of the movement and escapement as I could fill the page

with technicalities and each part requires different techniques,

however as this mechanism was particularly bad, a lot of the

parts did require a lot of hand polishing, degreasing, acid bath

and ultra-sonic cleaning. The original wooden rear slat re-glued

and a brace added for support that is hidden from view when

reassembled. ( Picture 7 ). The bell assembly is stripped and

critical parts polished and greased, the bell hammer readjusted and spring

re-tensioned. Once we are confident that all parts are moving

freely, and that all grease, old oiling attempts and lamp oil or

coal fire residue are removed, we reassemble the mechanism. (

Picture 8 ).

External Woodwork - VARIES ( Tru-Oil used on this example ) & Reassembly

Each metronome we select for rework is carefully assessed prior

to undertaking any work, this includes the existing external

woodwork and deciding the best course of action on things such

as how dry the wood is, wood grain, physical damage, water

damage, the status of any stains applied, whether it is an open

grained wood, scratches or gouges etc, before deciding what in

our opinion would be the best overall finish for each particular

metronome. While we do not get it right all of the time, we do

enjoy the process and lets face it, anything is better than how

this 99 year old metronome looked when we received it. Our

finishing is largely dependant on the original look of each

individual unit and on the age of the metronome. These include,

Danish and Tung Oils, Tru Oil ( used initially for gun stocks ),

varnish, stains and sealers, wax and in some cases such as

Walnut and Rosewood, 'Au Naturale'.

Having sanded the exterior to a very fine, silky base it became

evident that this particular metronome was quite unique ( Paquet

had a habit of selecting and constructing wonderful wood panels

with lovely grain and then covering it up or masking it, with

the external finish ) it has quarter sawn Cherry side panels,

both the left and right and standard cut Cherry front and back

panels, this results in an almost two toned appearance to the

overall look of the metronome. Whilst this may not be to

everybody's taste ( Paquet included ), we liked it and went with

just an oil, no stains, no sealers other than wet sand to fill

the pores. Seven coats in total. over the course of 3 days with

light abrasion with 0000 steel wool between the first 3 coats.

The result is a semi-gloss / gloss or polished appearance that

still retains an antiqued appearance,

durable, water-resistant and no finger marks or handling

evidence, it also has the bonus or being very easy to reapply in

the future should the metronome become scratched or worn and is

far more forgiving than a varnished finish for example. The

external brass fittings on this particular metronome have been

polished and reinstalled once the woodwork finish had properly

cured. The lower slat and rear foot repaired and felt added to the feet

bases. ( Picture 13 ).

The mechanism is replaced and we begin the process of balancing

and testing ( 3 Days ) to ensure the unit is performing within

our tolerance of +/- 5 beats per minute. This metronome

performed very well achieving 60 bpm for a total runtime of 45

minutes. The bell operating correctly but only on two of the four settings.

We hope you enjoy the results as much as we enjoyed undertaking

the transformation and hopefully given an insight into the work

involved and timeframes required.

Have one destined for the skip?

We are always interested in

purchasing Antique metronomes considered beyond repair or

destined to be discarded. We do require that the mainspring

operates and this can be determined by dropping us an email for

instructions or help on how to confirm this. The metronome would

also need to be salvageable, i.e not run over by a truck. Please

do not expect us to pay silly prices due to the work involved in

restoring poor quality metronomes, we will require quality

pictures to include the mechanism and a brief description of any

known issues or faults if possible. We do not purchase metronomes

post 1940. Thanks for reading!.

Brass Polishing:

We also offer a brass polishing service, where we remove all exterior brass fittings and polish to a high sheen which seems to be popular when matching a metronome to a piano for display purposes. We do not clean the fittings by default unless we feel the unit warrants it and any item shown on the website without cleaned brass-work is sold as viewed. We will however, under instruction polish fittings once a unit has been purchased for a standard charge of £9.95. Occasionally metronomes can be fitted with nickel silver or copper metal-work and in most cases these are best left to develop a deep handling patina. We will advise if we do not think that a unit would benefit from this service.